Cold Spray vs Thermal Spray – An Overview

What do the aerospace, shipping, oil, gas, and mining industries all have in common? They have high-dollar components that

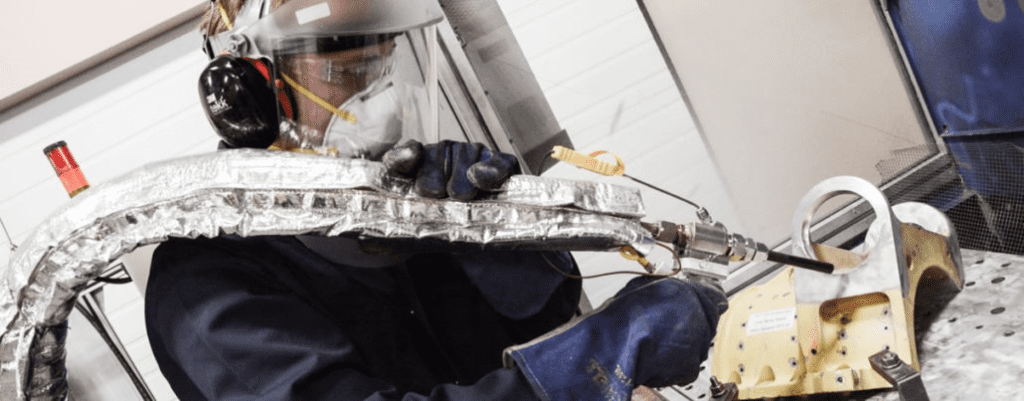

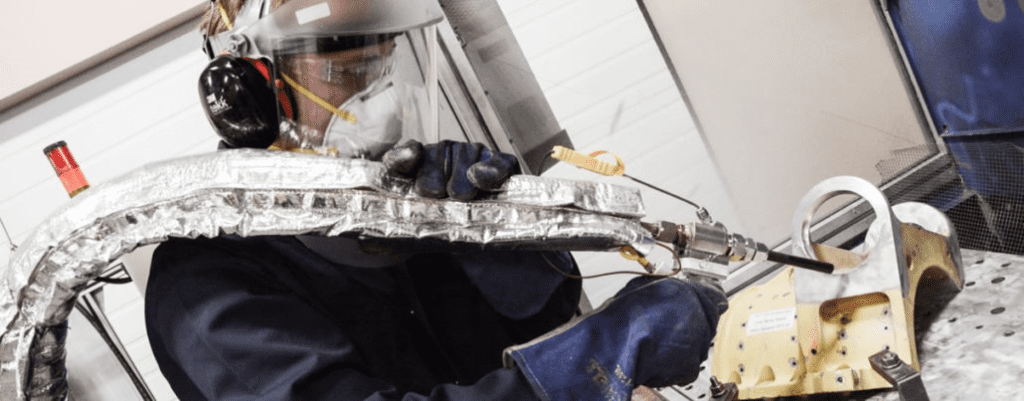

Process Development, Manufacturing, Installation and Integration of cold spray equipment are the reasons why we are the industry leader.

Have an application ideal for Cold spray but aren’t ready to commit the resources to bring it in-house?

VRC offers a wide variety of durable products to speed up or even completely automate your manufacturing processes.

VRC Metal Systems provides cold spray systems on a lease basis, which may be a more feasible approach for quick implementation

What do the aerospace, shipping, oil, gas, and mining industries all have in common? They have high-dollar components that

SAN DIEGO, Calif. (USNI News) – If a part breaks on a ship or submarine sailing in a conflict

Published: Sep. 4, 2023 RAPID CITY, S.D. (KOTA) – With the unit of B21 bombers scheduled to arrive at

Copyright © 2024 | VRC Metal Systems | Cold Spray Additive Manufacturing Experts

Get the exclusive 12-page info pack to find out how VRC helps fellow engineering organizations maximize their business output for free